CO/H2 Trim-Control

Adaptive Combustion Optimisation

Your advantages at a glance:

- Maximum energy savings through adaptive combustion optimization by starting up at the CO/H2 edge

- Improved control behavior through significantly shorter adjustment times and feedforward control via adaptive correction/learning curves

- Compensation for disturbance variables (air pressure, calorific value fluctuations, etc.)

- Fail-safe SIL2

- High operational reliability

- Solid, low maintenance, proven in operation

Adaptive combustion optimization by approaching the CO/H2 edge

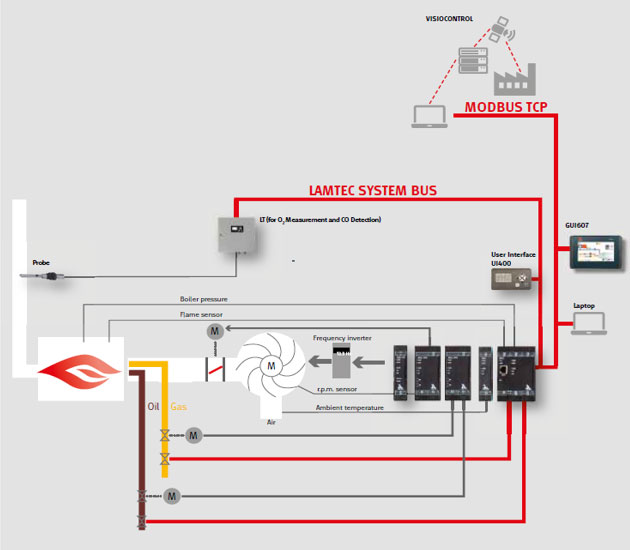

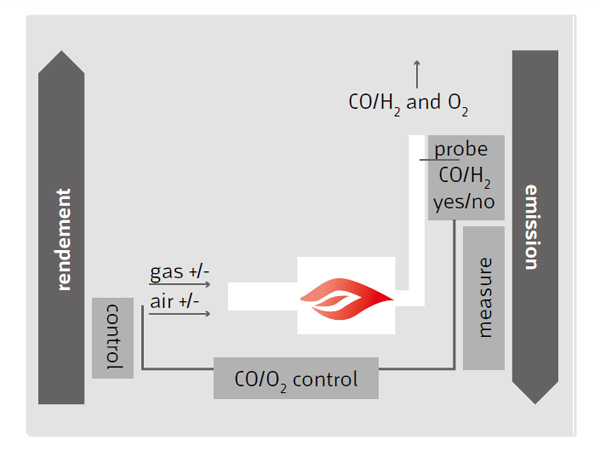

CO/H2 control is a software module in all LAMTEC combustion management systems (CMS, BT300, ETAMATIC, etc.). In combination with the LAMTEC O₂/COe measuring system LT3-F/KS1D, fuel consumption and pollutants are reduced to a minimum, thus conserving resources and protecting the environment. The system is fail-safe (SIL2). A modular CO/λ control system based on the LT3/KS1D has been developed for biomass combustion systems.

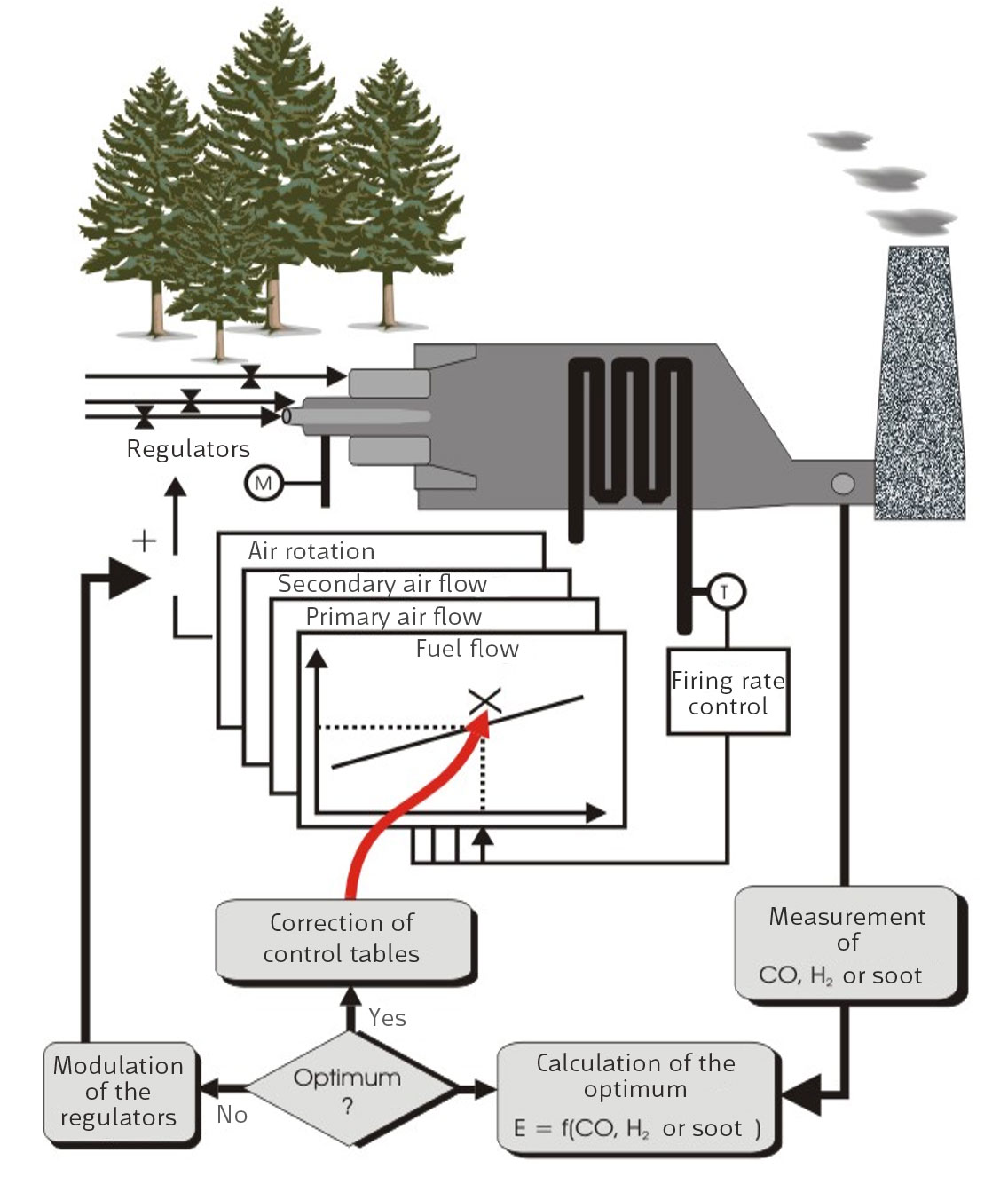

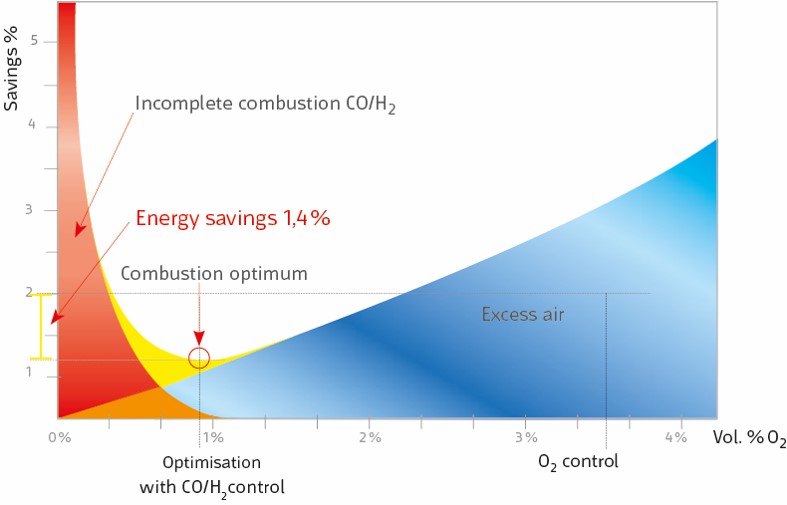

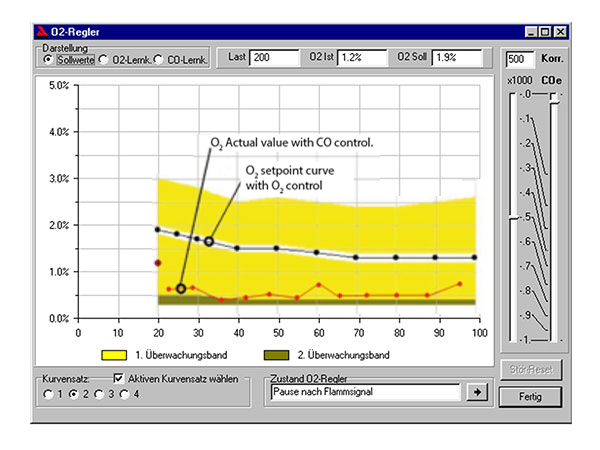

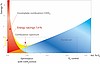

For decades, O2 control has been advancing energy efficiency in industrial combustion. It is based on the measurement of left over oxygen in the exhaust fumes. Disturbances such as false air can have an impact on the measurement and impair the functionality, efficiency, and safety of the control. The CO/H2 trim-control, integrated in the LAMTEC burner and compound control systems, equalises these disturbances and automatically optimises the fuel air ratio through repeatedly running to the emission edge. At the transition point from complete/good to incomplete/bad combustion, the emission edge marks the point at which combustion is optimised with minimal emissions, maximal combustion efficiency and minimal consumption.

At the emission edge products of incomplete COe combustion are formed. For detection of the emission edge specially developed LAMTEC exhaust gas sensors made from zirconium dioxide are available.

The combination probe KS1D for simultaneous measurement/detection of O2/COe can operate in an optimal way with the suitable sensor electronic, meaning via Lambda Transmitter (LT) or via the analog output of transmitter which provides multiple measured variables such as O2, COe, efficiency etc. All relevant variables for CO/H2 trim-control are passed on from the transmitter to the connected LAMTEC burner and compound control system via the LAMTEC System Bus (LSB).

Definition: COe is the sum of unburned components of exhaust gas such as CO, H2 and CXHY.

| Technical Data |

The fail-safe CO/H2 trim-control is based on a combination probe for simultaneous measurement/detection of O2/COe (KS1D) in combination with the according sensor electronic. The Lambda Transmitter (LT) sensor electronic is connected to a LAMTEC burner and compound control with integrated CO/H2 trim-control via the LAMTEC System Bus (LSB). The technial data of the CO/H2 trim-control depends on the system in use.

|

Further downloads can be found in the support section.

Deutsch

Deutsch

English

English

Francais

Francais