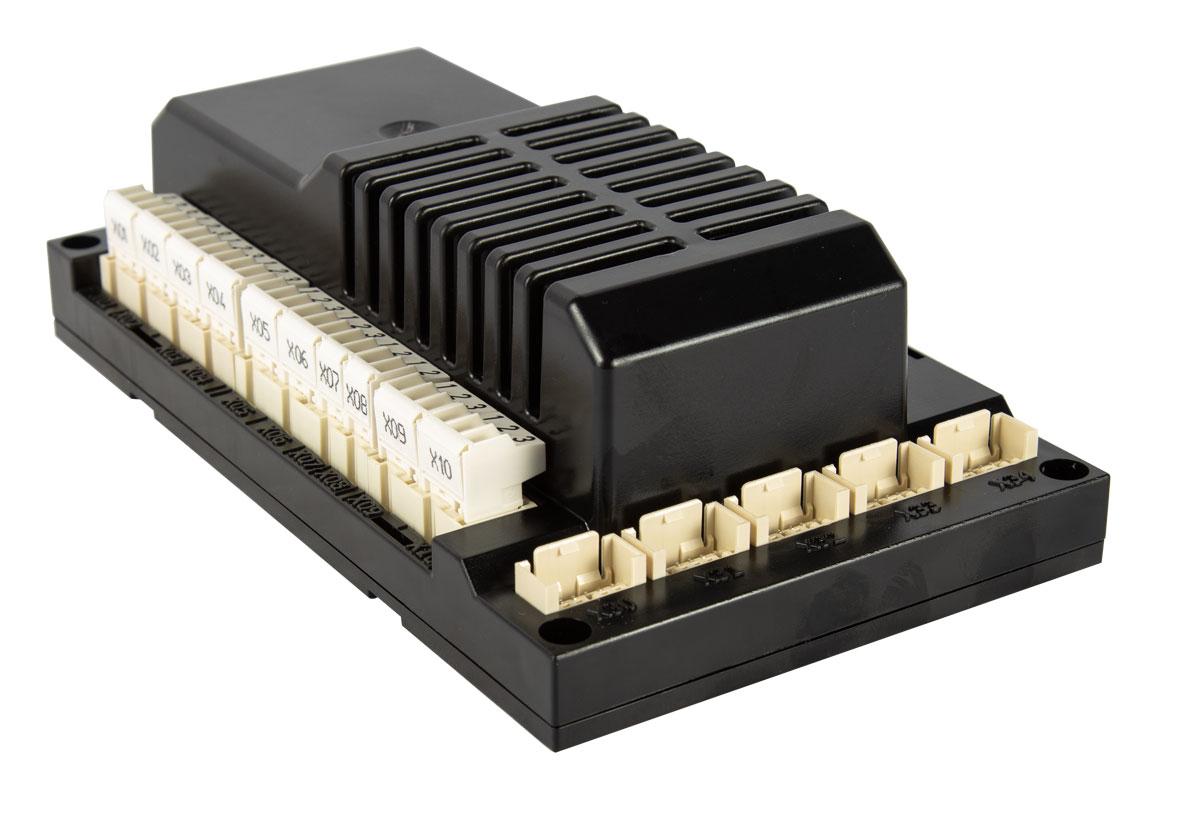

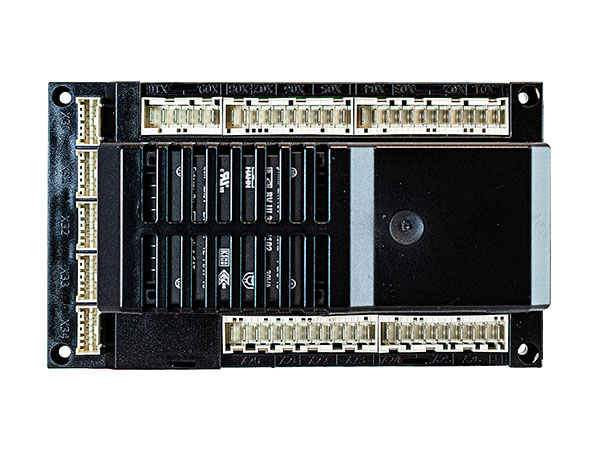

BurnerTronic BT300

Burner Control System

Your advantages at a glance:

- Modular burner control system

- Electronic compound with up to 4 channels

- Connectable to control instrumentation (system)

- Easy parameterisation via icon, adjustable via PC

- Integrated flame monitoring

- Firing rate controller (optional)

- Integrated valve leakage test (VLT)

- O2 regulation

- Adaptive CO/H2 combustion optimization (SIL2)

- Installation directly at the burner

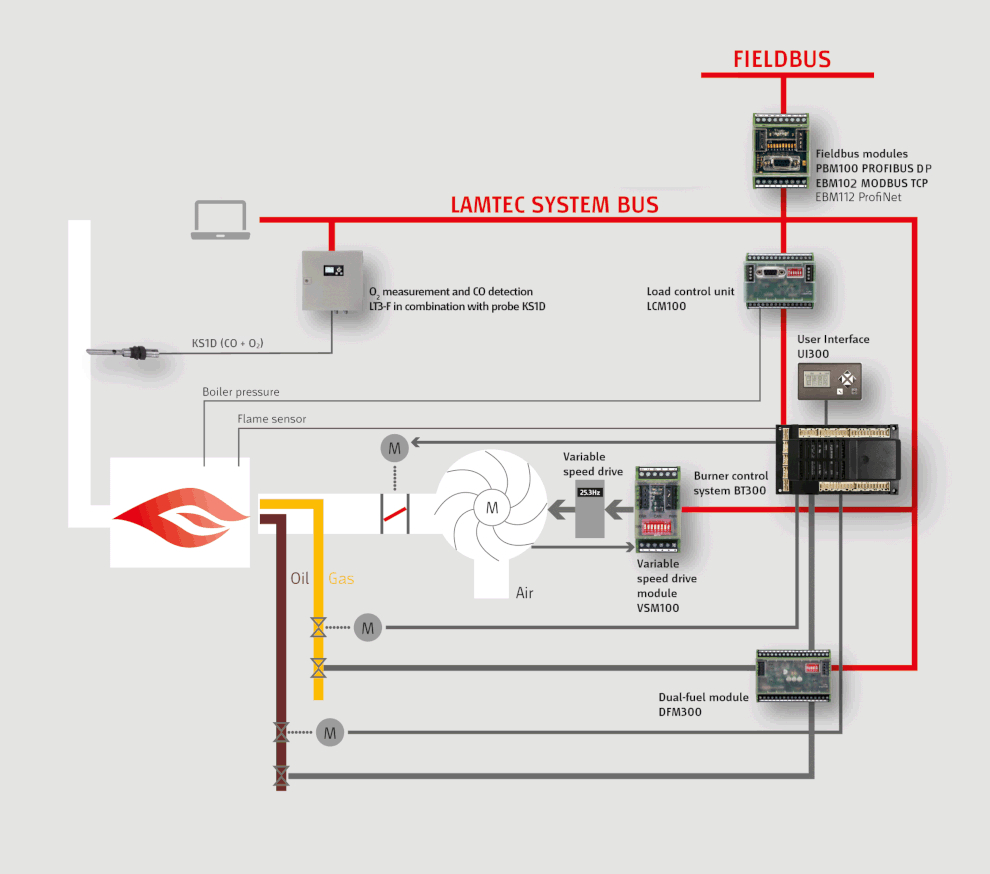

BurnerTronic BT300 combines the advantages of an electronic fuel/air compound control with an electronic burner control unit. Up to 3 motorised actuators are available. In addition, the BurnerTronic BT300 can be expanded by various modules, for example, by a module for speed control of the combustion air fan.

The basic version of the BurnerTronic BT300 has an integrated valve leakage check, flame monitoring, flue gas recirculation, operating hours and start-up counter.

A load control system as well as a O2 controller for optimising oil or gas-fired forced-draught burner are available as well. For adding this, a Lambda Transmitter LT1/LT2/LT3/LT3-F must be installed additionally.

The BurnerTronic BT300 is designed for direct mounting on the burner.

| Technical Data | |

| Approvals |

EC Type Examination Certificate (Module B) according to 2014/68/EU (Pressure Equipment Directive)

EC Type Examination Certificate according to 2016/426 (Gas Appliances Regulation GAR)

SIL 3

CE Declaration of Conformity

USA and Canada

|

Dual-fuel module DFM300

- Extension module for dual-fuel applications

- Connection via LAMTEC SYSTEM BUS (LSB)

- Oil/gas or gas/gas application

- Compatible with BT340 and BT341

- LCM/LEM required

RPM module VSM100

- Extension module for rpm control via inverter

- Feedback via Namur, 3-wire or analog signal

- Alternative: Connection of a 4th servomotor via 4..20mA/4..20mA

- Connection via LAMTEC SYSTEM BUS (LSB)

- Compatible with all BT300 variants

- LCM/LEM required

Load Controller Module LCM100

- Load controller module

- Switching between two programmed setpoints (optional)

- Control by atmospheric condition

- Additional functions:

- Gateway for connecting LSB devices

- Burner efficiency monitor output

- Fuel meter

- PT100/ PT1000 input for boiler, outdoor and flue gas temperature

- Connection via LAMTEC SYSTEM BUS (LSB)

- Compatible with all BT300 variants

LSB Interface Extension Module LEM100

- LSB interface extension module

- LAMTEC SYTEM BUS (LSB) interface for connecting additional BT modules

- Bus coupling to BT300

- Compatible with all BT300 variants

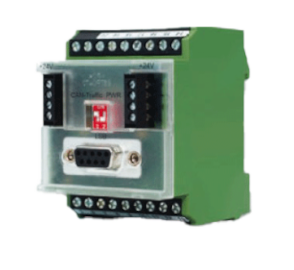

PROFIBUS DP PBM100 Field Bus Module

- Profibus DP field bus module

- Connection via LAMTEC SYSTEM BUS (LSB)

- Compatible with all BT300 variants

- LCM/LEM required

Modbus TCP EBM102 Field Bus Module

- Field bus module for Modbus TCP

- Connection via LAMTEC SYSTEM BUS (LSB)

- Compatible with all BT300 variants

- LCM/LEM required

PROFINET EBM112 Field Bus Module

- Field bus module for PROFINET

- Connection via LAMTEC SYSTEM BUS (LSB)

- Compatible with all BT300 variants

- LCM/LEM required

BT320 | BT330 | BT335 | BT340 | |

| Burner-Control-System for fuel … | Oil or Gas | Oil or Gas | Dual fuel operation | Dual fuel operation |

| Motorised actuator outputs | 2 | Up to 3 | Up to 3 | Up to 3 |

| Modulating oil operation / two-stage | Yes | Yes | Yes | Yes |

| Three-stage oil operation | Yes | Yes | X | Yes |

| Ignition valve | Yes | Yes | X | Yes |

| Approval for continuous operation with continuously operable flame scanner | X | Yes | Yes | Yes |

| POC / Reset input | Yes | Yes | X | Yes |

| Output for oil pump / burner Operating message | Yes | Yes | X | Yes |

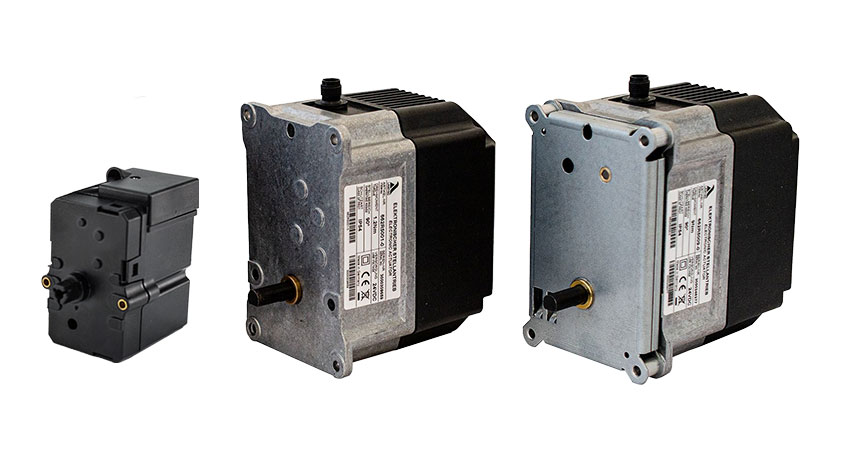

Actuators 662R5X

- from 0.8 Nm to 9 Nm

- Max. 3 actuators per BT-System

- TÜV-certificated for use with the BT300 and CMS AEC-ST module

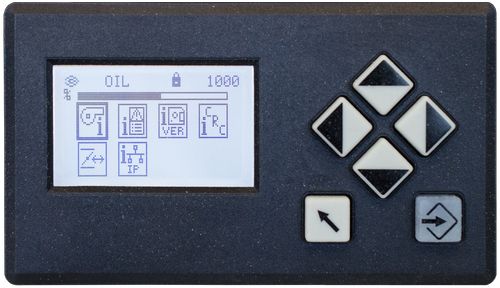

Simple language-neutral operation and parameterization using symbols

- Display UI300 and accessories

- Display UI300

- Cover IP65 for UI300 - Plug set

- Plug set - Additional modules

- Load Controller Module LCM100

- PROFINET EBM112

- Dual-fuel Module DFM300

- PROFIBUS Module PBM100

- Modbus TCP EBM102 - Actuators and Connection Cables

- Actuators from 0.9 to 9 Nm 662R5X

- Various connection cables - Dampers

- Gas dampers - Flame Monitoring

- Flame sensors KLC1000 / 2002

- Flame sensors FFS07/FFS08 with F152

- Flame scanner F200K, F300K - Remote Software

- LSB Remote Software for setting BC300, BT300, LT3 and LT3F

You can find additional accessories in the

product catalogue.

Accessories available via our sales representatives.

- Ionisation electrode (not part of the LAMTEC portfolio)

- KLC1000 Technical data

Further downloads can be found in the support section.

Deutsch

Deutsch

English

English

Francais

Francais