F300K

Compact Flame Scanner

Your advantages at a glance:

- Compact design

- 3 preselectable operating modes

- Available as single or dual sensor (UV/IR)

- Degree of protection IP66/IP67

- Flame ON/OFF self-learning function

- Measurement output for intensity 0-20 mA

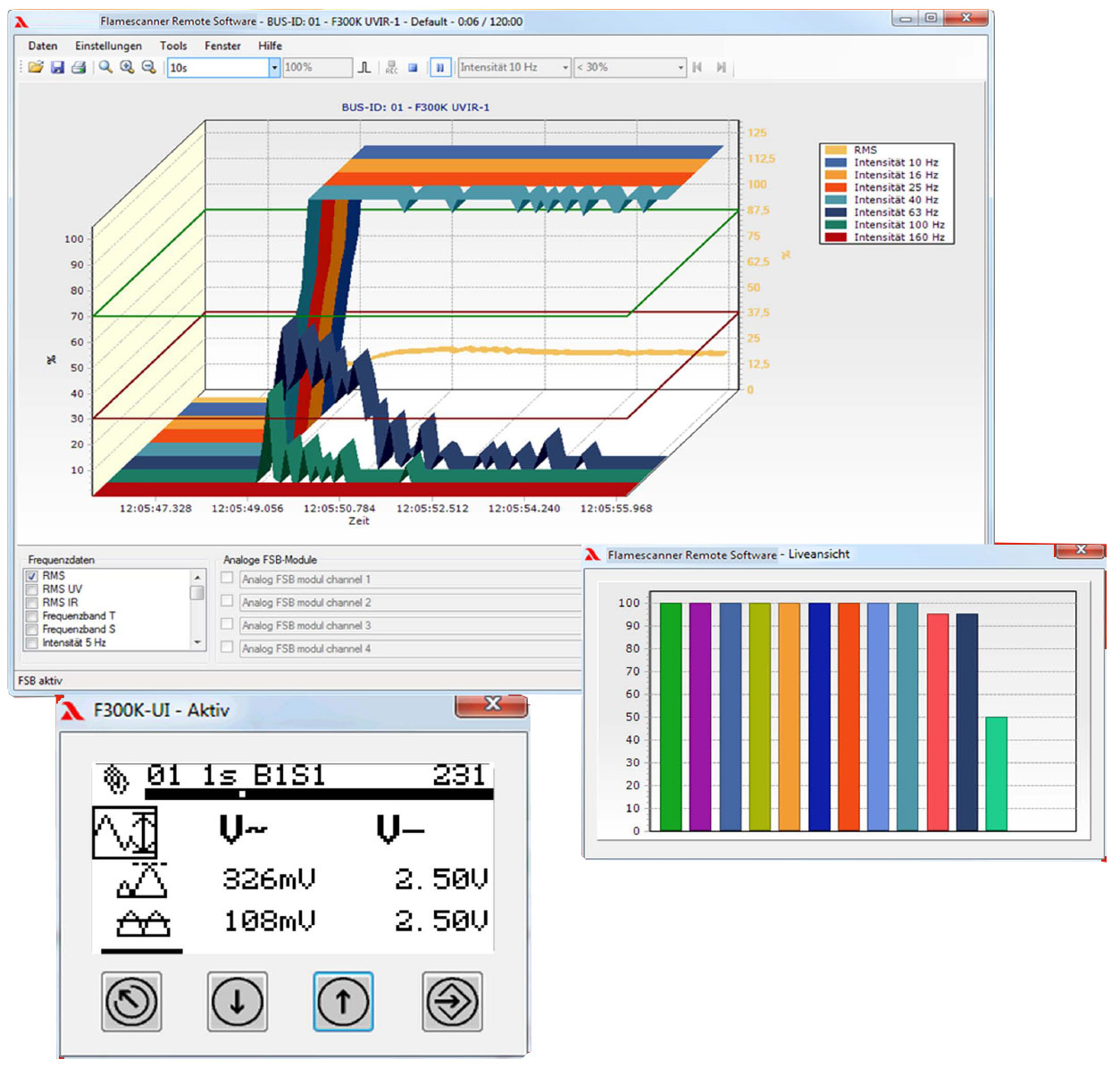

- Operation via graphic user interface with status display or F300K remote software, mandatory for versions without integrated user interface

- SIL 3 according to DIN EN 61508 parts 1-7

- Available with Class I, Division 2, group A, B, C, D, hazardous locations

- Ex 2 version

The F300K flame detector is the ideal solution for monitoring complex industrial firing systems. Designed as a compact flame monitor, it combines the evaluation unit and the flame sensor in one device. Thanks to its wide range of setting options and the UV/IR dual sensor version, it has already proven itself countless times under adverse conditions.

With the F300K, LAMTEC is offering for the first time a flame monitor that is able to evaluate the flame. The F300K is also approved for Ex Zone 2 and SIL 3 certified, which guarantees the highest safety standards and reliability.

The F300K is mainly used in…

- Complex combustion plants

- Combustion plants with and without selection tasks

- Single and combination burners

- Combustion chamber monitoring

- Power plants, heating plants, process furnaces, waste incineration plants

- Combustion plants with restricted view of the flame

Features:

3 in 1: Three flame scanners in one - Versatile, promising and highly intelligent.

The F300K flame scanners offer digital flame analysis in both the UV and IR spectral ranges, making them suitable for virtually all combustion applications.

Each model features a solid-state sensor with dual processors that provide continuous operation.

The F300K is a compact flame scanner with amplifier and relay units.

The F300K UV/IR model has dual UV and IR sensors, making it one of the most versatile flame scanners on the market.

It is suitable for demanding applications such as multi-burner installations with different fuels or excessive background radiation.

Three operating modes allow the application of specific detection parameters for different fuels and operating situations - so the F300K combines three flame scanners in one.

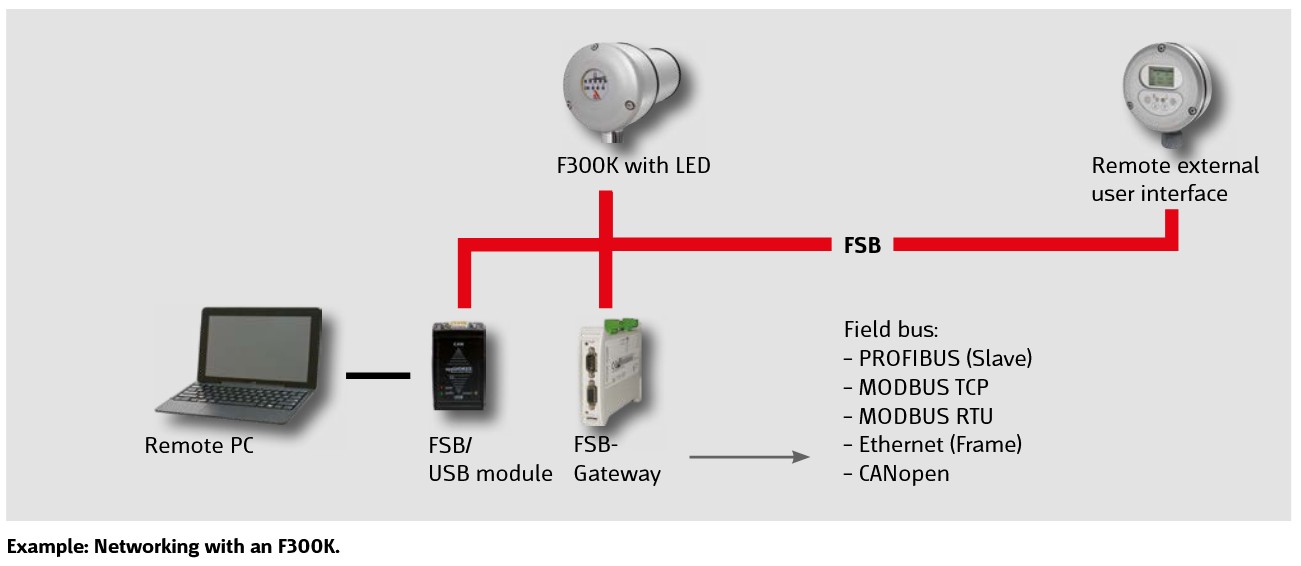

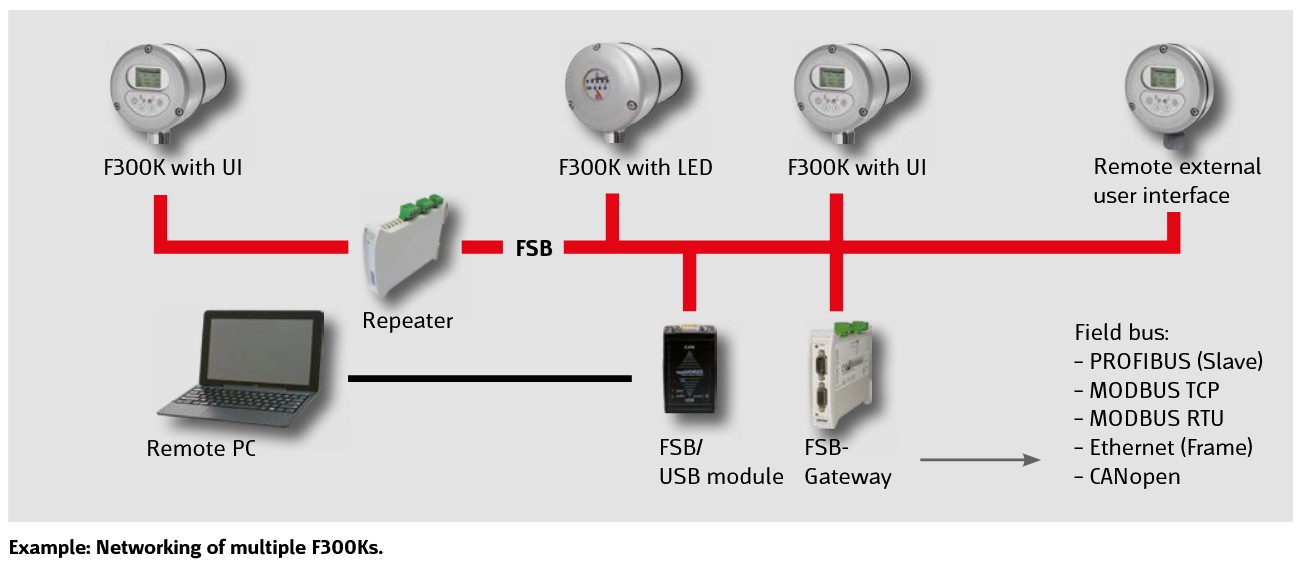

Up to 32 F300K scanners ...can be interconnected and connected to a PC to perform real-time flame analysis and record trends.

SIL 3 certified.

| Technical Data | |

| Approvals |

EC Type Examination Certificate according to 2014/68/EU (Pressure Equipment Directive)

EC Type Examination Certificate according to 2016/426/EU (Gas Appliances Regulation)

SIL 3

CE Declaration of Conformity

USA and Canada

EX certificate

|

| Compact | ||

| F200K | F300K | |

| Power supply voltage | 24 VDC | 24 VDC |

| Operating mode | Continuous operation | Continuous operation |

| Degree of protection Ex zone 1 | IP66 | X |

| Degree of protection Ex zone 2 | IP66/67 | IP66/67 |

| Sensor type | UV, IR | UV, IR, UV/IR-1 dual sensor |

| UV-2, (Ex zone 1, Ex zone 2), UV-6 FO (Ex zone 2), IR-1 (Ex zone 1, Ex zone 2), IR-2 (no Ex zone) | UV-4, UV-4.6, UV-4.6 FO, UV/IR-1, IR-4, UV/IR-1 FO (as standard all in Ex zone 2) | |

| Operating temperature Ex zone 2 | -40 °C ... +75 °C (UV-2, UV-6 FO) | -40 °C ... +85 °C |

| -40 °C ... +60 °C (IR-1) | ||

| Operating temperature Ex zone 1 | -40 °C ... +65 °C (UV-2) | X |

| -40 °C ... +60 °C (IR-1) | ||

| Ex zone 1 | Ex II 2G, zone 1 // Ex II 2D- zone 21 | X |

| Ex db lic. T6 ... T5 Gb // Ex tb IIIC T80 °C, T95 °C Db | ||

| Ex zone 2 | Ex II 3G, zone 2 // Ex II 3D zone 22 | Ex nA nC ic IIC T5 (T6) Gc X |

| Ex nA nC IIC T6 ... T5 Gc X // Ex tc IIIC T85 °C Dc X | ||

| UL resp. Class 1 Div. 2 certified | UL certified/ Cl 1 Div.2 | UL certified/ UL + Cl 1 Div. 2 |

| Operation with Remote Software | X | Yes |

| Evaluation device | Compact | Compact |

| Safety Integrity Level (SIL) | SIL 3 | SIL 3 |

| Non Compact | |||

| FFS07 | FFS08 | FFS30 | |

| Power supply voltage | F152 + 24 VDC | F152 + 24 VDC | F350 + 24 VDC |

| Operating mode | Continuous operation | Continuous operation | Continuous operation |

| Degree of protection | IP66 for Ex zone 1 | X | IP66 |

| IP67 for Ex zone 2 | No Ex zone only as standard IP67 | IP67 | |

| Sensor type | UV, IR | UV, IR | UV, IR, UV/IR-1 Dual sensor |

| UV-1, UV-4, IR-1, IR-1 T | UV-1, UV-4, IR-1, IR-1 T, IR-1 T/S2 | UV-4, UV/IR-1, IR-2, IR-4 | |

| Operating temperature | -20 °C ... +65 °C (UV) | -20 °C ... +65 °C | -40 °C ... +85 °C |

| Operating temperature | -20 °C ... +60 °C (IR) | -20 °C ... +60 °C | |

| Ex zone 1 | II 2G Ex d IIC T6 Gb | II 2G Ex d IIC T6 Gb | |

| II 2D Ex tb IIIC T80 °C Db | X | II 2D Ex tb IIIC T80 °C Db | |

| Ex zone 2 | II 3G Ex nA IIC T5 (T6) Ge X | X | X |

| II 3D Ex tc IIIC T95 °C Dc X | X | X | |

| Display | X | X | Has to be connected with FB 30 |

| UL resp. Class 1 Div. 2 certified | UL 372 - UL listed | UL 372 - UL listed | UL / Cl 1 Div. 2 |

| Operating with Remote Software | X | X | Yes |

| Evaluation device | F152 | F152 | F350 |

| Safety Integrity Level (SIL) | F152 SIL 3 | F152 SIL 3 | F350 SIL 3 |

You can find additional accessories in the

product catalogue.

Accessories available via our sales representatives

Further downloads can be found in the support section.

Deutsch

Deutsch

English

English

Francais

Francais