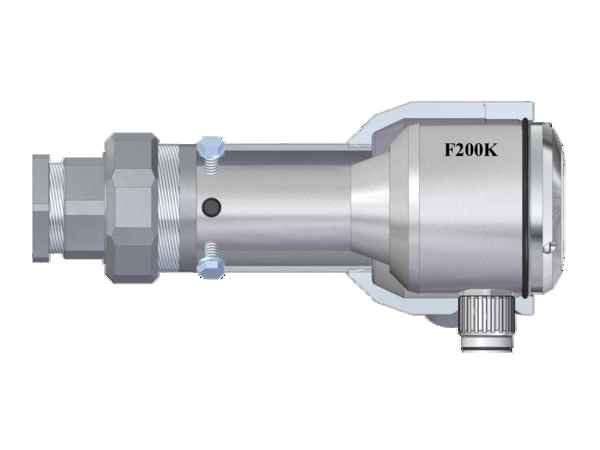

F200K / F200K Ex-II

Compact Flame Scanner

Your advantages at a glance:

- Compact flame scanner

- For single-burner and multi-burner systems, continuous operation

- Compact housing with integrated flame sensor and circuit amplifier

- Multi-level sensitivity adjustment

- Digital flame frequency evaluation

- Status display via LED

- Measurement output for intensity 0-20 mA

- 2 channel system with electronic self-monitoring

- Connectable trend display for optimal flame adjustment

- SIL 3 according to DIN EN 61508-2

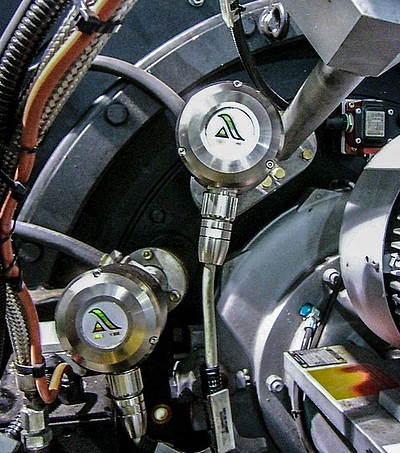

The F200K is mainly used as a single and multi-fuel burner in large power plants, heating plants, chemical plants, waste incineration plants and combustion plants with a restricted view of the flame. It can be used for monitoring firing systems, that are operated with

- Oil

- Gas

- Hydrogen

- Biomass

- Special gases such as refinery and blast furnace gases

- Wood

- Coal

- Firings with strong flue gas recirculation

- Waste gases with a yellowish colour without UV radiation or shielding of the UV components by water vapour, dust...

Features:

The compact flame scanners can be used for a wide variety of applications and almost all monitoring tasks.

The flame scanners takes over the safety-related monitoring of burner flames in single and multi burner firing systems.

When the flame is extinguished, the safe switching state "flame OFF" is reached.

- 2 pre-set operating modes

- No special aids are required for commissioning

- Optionally available for Ex zone 2

- SIL 3

| Technical Data | |

| Approvals |

EC Type Examination Certificate according to 2014/68/EU (Pressure Equipment Directive)

EC Type Examination Certificate according to 2016/426/EU (Gas Appliances Regulation)

SIL 3

CE Declaration of Conformity

USA and Canada

EX certificate

|

| Compact | ||

| F200K | F300K | |

| Power supply voltage | 24 VDC | 24 VDC |

| Operating mode | Continuous operation | Continuous operation |

| Degree of protection Ex zone 1 | IP66 | X |

| Degree of protection Ex zone 2 | IP66/67 | IP66/67 |

| Sensor type | UV, IR | UV, IR, UV/IR-1 dual sensor |

| UV-2, (Ex zone 1, Ex zone 2), UV-6 FO (Ex zone 2), IR-1 (Ex zone 1, Ex zone 2), IR-2 (no Ex zone) | UV-4, UV-4.6, UV-4.6 FO, UV/IR-1, IR-4, UV/IR-1 FO (as standard all in Ex zone 2) | |

| Operating temperature Ex zone 2 | -40 °C ... +75 °C (UV-2, UV-6 FO) | -40 °C ... +85 °C |

| -40 °C ... +60 °C (IR-1) | ||

| Operating temperature Ex zone 1 | -40 °C ... +65 °C (UV-2) | X |

| -40 °C ... +60 °C (IR-1) | ||

| Ex zone 1 | Ex II 2G, zone 1 // Ex II 2D- zone 21 | X |

| Ex db lic. T6 ... T5 Gb // Ex tb IIIC T80 °C, T95 °C Db | ||

| Ex zone 2 | Ex II 3G, zone 2 // Ex II 3D zone 22 | Ex nA nC ic IIC T5 (T6) Gc X |

| Ex nA nC IIC T6 ... T5 Gc X // Ex tc IIIC T85 °C Dc X | ||

| UL resp. Class 1 Div. 2 certified | UL certified/ Cl 1 Div.2 | UL certified/ UL + Cl 1 Div. 2 |

| Operation with Remote Software | X | Yes |

| Evaluation device | Compact | Compact |

| Safety Integrity Level (SIL) | SIL 3 | SIL 3 |

| Non Compact | |||

| FFS07 | FFS08 | FFS30 | |

| Power supply voltage | F152 + 24 VDC | F152 + 24 VDC | F350 + 24 VDC |

| Operating mode | Continuous operation | Continuous operation | Continuous operation |

| Degree of protection | IP66 for Ex zone 1 | X | IP66 |

| IP67 for Ex zone 2 | No Ex zone, as standard IP67 only | IP67 | |

| Sensor type | UV, IR | UV, IR | UV, IR, UV/IR-1 Dual sensor |

| UV-1, UV-4, IR-1, IR-1 T | UV-1, UV-4, IR-1, IR-1 T, IR-1 T/S2 | UV-4, UV/IR-1, IR-2, IR-4 | |

| Operating temperature | -20 °C ... +65 °C (UV) | -20 °C ... +65 °C | -40 °C ... +85 °C |

| Operating temperature | -20 °C ... +60 °C (IR) | -20 °C ... +60 °C | |

| Ex zone 1 | II 2G Ex d IIC T6 Gb | II 2G Ex d IIC T6 Gb | |

| II 2D Ex tb IIIC T80 °C Db | X | II 2D Ex tb IIIC T80 °C Db | |

| Ex zone 2 | II 3G Ex nA IIC T5 (T6) Ge X | X | X |

| II 3D Ex tc IIIC T95 °C Dc X | X | X | |

| Display | X | X | Must be connected with FB 30 |

| UL resp. Class 1 Div. 2 certified | UL 372 - UL listed | UL 372 - UL listed | UL / Cl 1 Div. 2 |

| Operating with Remote Software | X | X | Yes |

| Evaluation device | F152 | F152 | F350 |

| Safety Integrity Level (SIL) | F152 SIL 3 | F152 SIL 3 | F350 SIL 3 |

| Brackets with screw connection |  |

| Connecting cable |  |

| Fiber Optik |  |

| Flame Scanner Testing Device FFP30 |  |

| Power supplies |  |

| Cooling air housing |  |

| Junction box |   |

| Thermojacket |  |

You can find additional accessories in the

product catalogue.

Accessories available via our sales representatives

Further downloads can be found in the support section.

Deutsch

Deutsch

English

English

Francais

Francais