O2 Trim-Control

Combustion Optimisation

Your advantages at a glance:

- Energy savings

- Reduces pollutant emissions (NOx, CO2, CO, etc.)

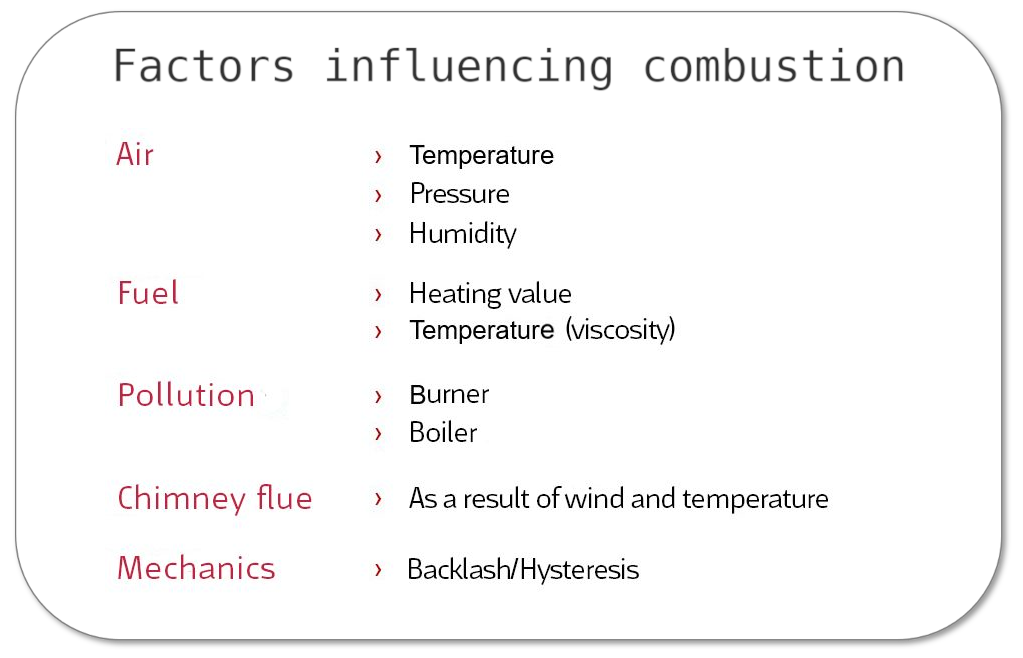

- Compensation for disturbances (e.g., air pressure, heating value fluctuations, etc.)

- Proven feedforward control for firing rate changes via adaptive correction/learning graphs

- High operational reliability

- Solid, low-maintenance, proven in operation

- An integrated PID O2 trim-control is available as an option for the LT1/LT2 lambda transmitter.

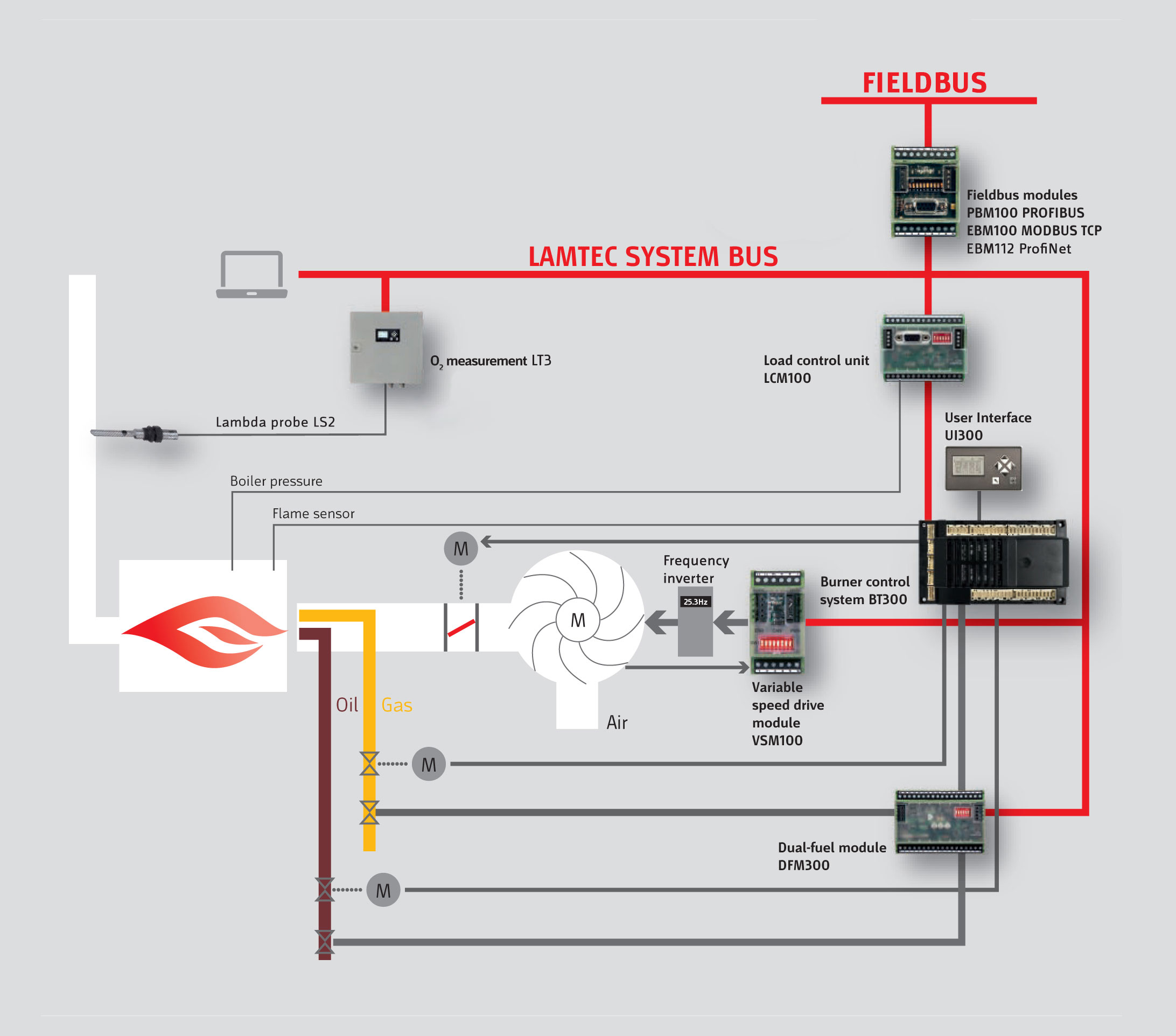

The O2 trim control is a software module of all LAMTEC burner management systems (CMS, BT300, ETAMATIC, etc.). It is used in combination with the LAMTEC O2/exhaust gas measuring devices LT1, LT2, LT3, LT3-F, and NT1.

The O2 trim control optimizes combustion by regulating the oxygen content in the combustion process according to the optimum burner-specific O2 setpoint, thereby compensating for disturbances affecting combustion. This saves fuel, reduces pollutant emissions, and compensates for disruptive influences.

The result:

An efficient, cost-saving, and environmentally friendly solution for heating systems and process plants.

The O2 trim control system aims to compensate for disturbances affecting combustion and to regulate the optimum O2 value specified for the operating condition.

Disturbances can lead to significant changes in the residual oxygen content in the exhaust gas of an uncontrolled combustion system. This can potentially result in hazardous conditions for the system. An O2 trim-control maintains the oxygen level in the exhaust gases stable and compensates for nearly all disturbances.

Examples of the influence potential of the following disturbances:

| Disturbances of combustion | Typical fluctuations | O2 Change in Vol. % |

| Air temperature | ± 20 °C | 1.0 - 1.5 Vol. % |

| Air pressure | ± 25 mbar | ± 0.5 Vol. % |

| Calorific value | ± 10 % | 2.0 - 2.8 Vol. % |

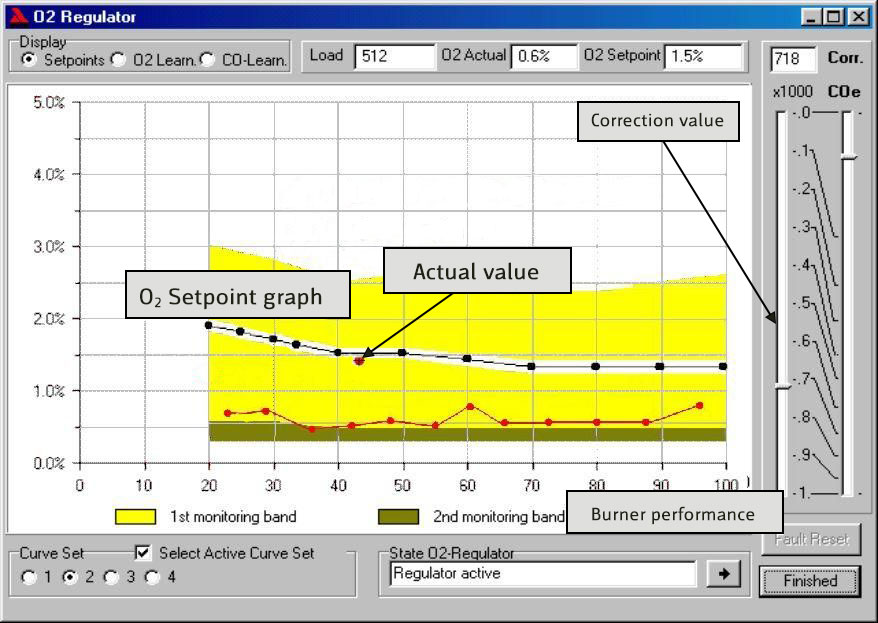

A universal PID controller module is implemented in the LT1/LT2 and can be activated as an option. Alternatively, a fixed setpoint or a load-dependent setpoint curve can be set as the O2 setpoint. The setpoints and setpoint graphs can be entered for up to 4 fuels. The fuel specification is made via the digital inputs. The PID O2 trim-control compares the measured residual oxygen value in the exhaust gas with the setpoint and corrects the fuel/air ratio via the continuous controller output until the setpoint and actual values match. The controller output is advantageously connected to an electronic fuel/air composite control system. However, direct connection to an air damper or fuel control device via a servomotor with positioning electronics is also possible. In the event of burner start-up, malfunction, maintenance, etc., a fixed, parameterizable replacement value is output. Up to 4 limit values/limit value graphs can be activated for monitoring purposes, based on the specified setpoint graph.

Further downloads can be found in the support section.

Deutsch

Deutsch

English

English

Francais

Francais